Human resources policy

People are the most valuable resource of a company. Adhere to the people-oriented, treat people as a special resource to deliberately dig, scientific management and evaluation, maximize and enhance each person's talents, and enable them to develop in a direction that is conducive to achieving the company's goals, so that the company The required talents can be supplied in a timely, appropriate and appropriate manner. Every employee of the company has its own place and do their best. This is the company's human resources policy.

In order to achieve this goal, the Human Resources Department and all management cadres will continue to innovate and forge ahead, and make unremitting efforts to establish a systematic, scientific, rigorous and standardized human resources system.

Supplier development management

The company has developed more than 200 suppliers for the development of car audio movements, automotive electronics, automotive lenses, security lenses, precision optical components, etc. These suppliers are Japanese, private, US, Hong Kong, and Taiwanese. , Korean capital, joint ventures, state-owned enterprises, etc., involving bald heads, motors, stamping, injection molding, PCB, rubber, hardware, electronic components, wire, connectors and other industries, there are many well-known suppliers in each industry.

The company cooperates with various suppliers in the spirit of fairness, justice and mutual benefit, and sincerely hopes to become a long-term strategic partner. With the continuous development and development of new products and new businesses of the company, we welcome more new partners to join us and provide better products and services to our customers.

Market development management

The Market Development Department is responsible for the promotion and sales of the company's products and the business of taking orders. It regularly collects market information,feedbacks customer needs and expectations, and conducts effective analysis of market information.

The company adheres to the customer's needs as the center, and has established an effective sales management system and incentive system to provide customers with satisfactory products and services while bringing the company's products to the market quickly. East China have set up business offices to expand the channels of communication and communication with customers. The company's products have a good reputation and reputation in the domestic and foreign markets.

It is our consistent pursuit to serve customers and customers to develop together and achieve a win-win situation.

Product development management

In the management of R&D systems, the company establishes and continuously standardizes the system knowledge of applying new product development life cycle management and project management methods based on the implementation of management systems such as IS09001, IATF16949, ISO14001 and ESD S20.20. And improve the company's R & D organization management, R & D project financial management, has established the "Design Control and APQP Management Procedures", "R & D New Product Development Manual", "Project Manager Responsibility System", "Technology Accumulation Management System", "R & D R&D management system such as reserve management system, R&D project input accounting system, and R&D incentive system such as “Science and Technology Innovation Incentive System” and “Patent Management and Incentive System”.

The company has a well-organized R&D management team. The R&D system consists of two full-time R&D centers: electronic R&D center and optical R&D center. It also has R&D optical department, BMS department, software department, module department, testing department, pilot test department, management department and other functional sub-departments. It has optical design, structural design, electronic hardware design, software design, process design, and management department. R&D testing, R&D project management and other aspects of the professional team. The company has invested more than 20 million yuan to establish a new product pilot test and reliability test center, which provides a strong infrastructure and equipment guarantee for the smooth development of new research and development projects.

In recent years, through independent research and development, our company has obtained patents and technologies for many products related to automotive core servo, automotive bluetooth, lithium battery power management system, automotive lens, automotive WIFI module and other products. We have accumulated 12 invention patents, 113 utility model patents, 23 design patents, 148 patents, and 5 computer software copyright registration. Item. And participated in one national standard GB/T 26775-2011 "General Technical Conditions for Vehicle Audio and Video Systems" and four communication industry standards YD/T 344.2-2015 "Lithium Iron Phosphate Battery Pack for Communication Part 2: Separate Battery Pack", "YD/T 3088-2016" 336V Rectifier for Communications","YD/T 3089-2016"336V DC Power Supply System for Communications", "YD/T 3091-2016" 240V/336V DC Power Supply System for Communications Establishment of Requirements and Methods for Post-Operational Assessment. The company's patented technological achievements have been successfully transformed into volume production and sales. The company's self-developed car core products have accounted for 60-70% of the domestic car audio market of medium and high-grade cars. At the same time, the company's car-borne bluetooth, car-borne WIFI, car-borne lens, BMS (lithium battery management system) and other new products have also achieved volume production and sales, and have been recognized and praised by many customers.

The company has a solid and solid research and development foundation, and will adhere to the market-oriented, customer-centric product development concept, in order to provide customers with higher value products and services as the goal, and constantly improve the product development management system. .

Quality Control

Establish ISO9001, iatf16949 quality system, IS014001 environmental management system, iso45001 occupational health and safety management system, ESD s20.20 electrostatic discharge management system, QC080000 hazardous substances management system, ISO27001 information security management system and network security management system, implement internal audit and management review every year, and continuously improve.

Implement a management model of target management and process control.

Each year, with continuous improvement of ideas, new levels of goals are identified.

The performance of the evaluation is continuously improved according to the determined quality objectives every month.

A quality meeting is held every month to comprehensively summarize the work of this month; the quality meeting of all parties of the group is held once a month to communicate the information of domestic and foreign customers and parties within the group.

The performance of suppliers is evaluated monthly, and supplier meetings are held regularly to improve the quality of incoming materials.

Improve production methods and carry out 18 basic management tasks. Including lean production and amoeba, rationalization advice, kanban management, digestion and absorption of new products, case analysis, analysis and exchange meetings, economic responsibility system, production line economic responsibility system, production site responsibility system, process inspection, countermeasure table tracking, Workers' monthly awards, management manuals, monthly reports, training, routine tests, etc.

Staff training includes on-the-job training, general knowledge training, job skills training, transfer training, on-the-job training, etc., including: ISO9001, ISO14001, IATF16949, QC08000, ESD S20.20 and other standards or specifications, product assembly technology, manufacturing process, IE, TPM, 6σ, FMEA, SPC, MSA, 8D, QC seven tools, 5S management, etc. should know the content.

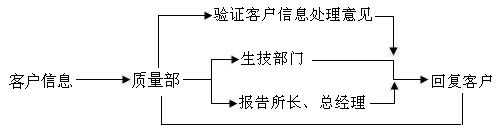

Customer Information Feedback Process

Production and management

In 2006, the company introduced a world-class SAP software management system; later introduced MES manufacturing execution system, OERP system, HR system, PAS system, PPC system, which greatly improved the information management level and response speed. The company's information management level has achieved a qualitative leap;

The production management of the company takes the production management department / Manufacturing Department of each business institute as the window, including original price management, order management, material procurement, production plan, daily production, production statistics and delivery management. Each production management department regularly makes three-month rolling production plans and monthly plans, and counts the actual performance of daily production and delivery.

The long-term business plan and development strategy shall be determined by the Chinese and foreign board of directors from time to time.

The company holds monthly business meetings for all parties of the group to communicate information on operation, production, supply and marketing.

The company implements three responsibility systems and AMB accounting system, i.e. the economic responsibility system of the Department, the economic responsibility system of the production line and the on-site management responsibility system. It makes statistics, analysis and annual assessment on the business indicators, quality indicators and AMB related data of each business institute (Department) every month.

Comprehensive implementation of lean management and technological transformation activities to eliminate waste and improve production and management efficiency.

Quality needle

Quality is the eternal theme of business management.

It is our quality policy to continuously develop and manufacture high quality products, provide quality services, and continuously improve to meet customer requirements and improve economic efficiency.

In order to achieve this goal, every employee of the company should be determined to understand the quality system established by the company in accordance with ISO9001 standard and IATF16949 technical specifications and QC080000 system requirements and ESD S20.20 system requirements, and is committed to doing the first and every time.

Environmental policy

There is only one earth on which mankind lives. The resources of the earth are limited. Maintaining a good environment is a need to meet the healthy and sustainable development of today's and tomorrow's generations.

Shinwa Company is committed to protecting the environment while planning new project products and developing the economy. All activities consider environmental benefits, create a modern green corporate image that the public and the society appreciate, and promise to the whole society:

1. Comply with environmental laws, regulations and other requirements.

2. Use non-toxic (or less toxic) alternatives wherever possible in product/process design and other activities. Minimize waste generation and safe disposal with appropriate pollution prevention techniques.

3. Save energy and reduce consumption and train employees on environmental awareness, knowledge and skills.

4. Committed to environmental protection, sharing environmental management experience, strengthening exchanges and cooperation with relevant parties, and continuous improvement.

Occupational Health and Safety

Abide by the regulations and laws, prevent accidents, participate in continuous improvement, and ensure the health and safety of employees

Information security policy

Active prevention and continuous improvement, everyone is responsible for information security